WasteEng22 “9th International Conference on Engineering for Waste and Biomass Valorisation” 27th-30th June, 2022 – Copenhagen, DENMARK

17 years highlighting Research & Innovation in Waste and Biomass Valorisation towards Energy and Environmental Transitions.

At the heart of sustainable development, the WasteEng conferences have been developed to advance the green economy, to make it more resource efficient, resilient to climate change and in sync with the natural environment. While focused on scientific and technological advances, the topics covered are very concrete, such as life cycle assessment and technologies/processes/practices that reduce GHG emissions.

BlackCycle consortium with CPERI-CERTH propose an abstract at the 9th International Conference on Engineering for Waste and Biomass Valorisation

PYROLYSIS OF END-OF-LIFE TYRES COUPLED WITH CATALYTIC VAPOUR UPGRADING – 27th–30th June 2022 by S.D. Stefanidis, S.A. Karakoulia, E. Pachartouridou, E. Heracleous, A.A. Lappas

PYROLYSIS OF END-OF-LIFE TYRES COUPLED WITH CATALYTIC VAPOUR UPGRADING

Abstract

Highlights

- Conversion of end-of-life tyres into raw materials for the production of new tyres

- Production of 35% recovered carbon black and 53% pyrolytic oil

- Catalytic vapour upgrading increased the aromaticity of the pyrolytic oil

- Pyrolytic oil with >85 wt% aromatics content achieved with Y-zeolite catalysts

Purpose

A large number of tyres from road vehicles are retired annually, entering the pool of end-of-life tyres (ELTs) that presents a large, untapped potential for material recovery. Tyres are complex composites made up of elastomers, fillers, reinforcement materials, chemicals and plasticisers, many of which are produced from non-renewable sources. While ELTs can be treated to be repurposed for various applications, today’s treatment processes are not circular and do not result in many raw materials that can be reused in new tyres. The BlackCycle project aims to develop technology for the recycling of ELTs into raw materials that can be used for the production of new tyres, effectively reducing the use of composites from non-renewable sources and drastically mitigating CO2 emissions. In this work, pyrolysis of an ELT feed was carried out to obtain raw materials; carbon black and pyrolytic oil. The pyrolysis temperature was optimised to maximise the recovery of the pyrolytic oil and to minimise the formation of non-condensable gases. A range of catalysts were screened for the catalytic upgrading of the ELT pyrolysis vapours in order to maximise the aromatic content of the pyrolytic oil so that it can be used for the further production of carbon black.

Materials and Methods

The ELT feed was provided by ALIAPUR, an end-of-life tyre recycling company in France, and ESTATO Umweltservice Gmbh, a waste management company in Germany, and it was composed of shredded truck tyres. The pyrolysis and catalyst screening experiments were carried out in a fixed bed pyrolysis reactor [1]. The catalysts used were an ultra-stable Y zeolite catalyst (USY), a ZSM-5 zeolite catalyst (ZSM-5), a MgO catalyst, a cobalt-promoted ZSM-5 catalyst (Co/ZSM-5) and a nickel-promoted USY catalyst (Ni/USY). Non-condensable gases were analysed by gas chromatography, while the pyrolytic oils were analysed by CH elemental analysis (ASTM D5291), simulated distillation (ASTM D- 6352), PIONA analysis for the determination of the aromatics content of the gasoline-fraction (ASTM D-6733) and HPLC for the determination of the total aromatics content (EN 12916).

Results and discussion

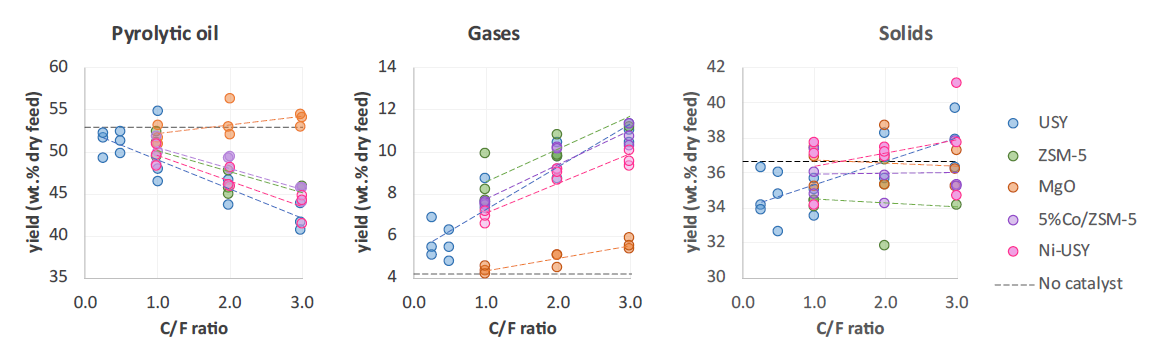

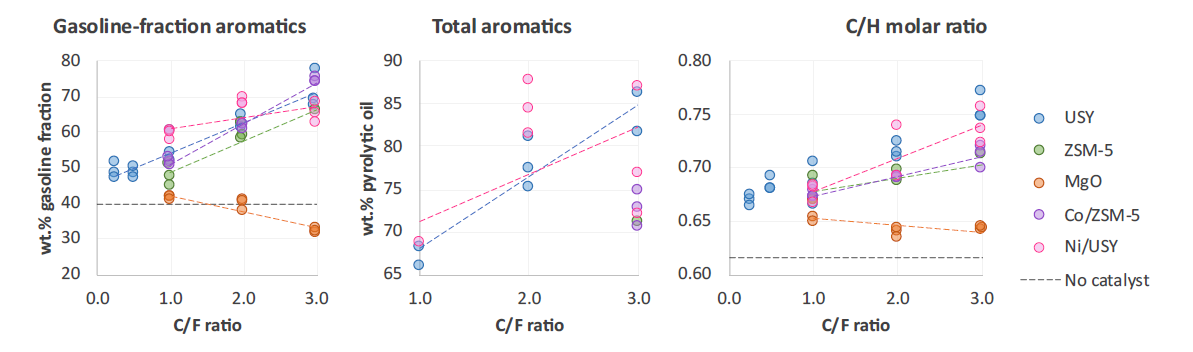

Pyrolysis of the ELT feed was carried out at 500, 550 and 600 °C. The maximum yield of pyrolytic oil (53 wt%) was observed at 500 °C, while the yield of the carbon black was constant (35 ± 1.3 wt%) for all pyrolysis temperatures, indicating the complete pyrolysis of the ELT feed at 500 °C. Higher temperatures favoured the formation of gases at the expense of the pyrolytic oil. They also resulted in pyrolytic oils composed of lighter compounds, with C/H molar ratios of up to 0.63, and with up to 51 wt% aromatics in the oil’s gasoline fraction. The use of catalysts for the upgrading of the pyrolysis vapours resulted, in most cases, in decreased pyrolytic oil yields due to catalytic cracking reactions, producing uncondensable gases and coke deposits on the catalyst (Figure 1). This decrease however was accompanied by a substantial increase in the C/H molar ratio (up to >0.75) and in the aromatics content (up to >85 wt%, Figure 2) of the pyrolytic oils, and as such, in increased suitability for their use as a raw material for carbon black and for the recovery of high added value aromatic compounds, especially in the case of the USY catalysts.

Figure 1. Pyrolytic product yields from the catalytic pyrolysis of the ELT feed at 500 °C, as a function of the catalyst-to-feed (C/F) ratio.

Figure 1. Pyrolytic product yields from the catalytic pyrolysis of the ELT feed at 500 °C, as a function of the catalyst-to-feed (C/F) ratio.

Figure 2. Composition of the pyrolysis oils from the catalytic pyrolysis of the ELT feed at 500 °C, as a function of the C/F ratio.

Figure 2. Composition of the pyrolysis oils from the catalytic pyrolysis of the ELT feed at 500 °C, as a function of the C/F ratio.

Conclusions and perspectives

ELTs can be pyrolysed to produce raw materials that can be reused in the tyre industry; carbon black and pyrolytic oil. Catalytic upgrading of the pyrolysis vapours can significantly increase the aromatic content of the pyrolytic oil, increasing its suitability for the production of carbon black and for the recovery of valuable aromatic chemicals. This enables a more circular tyre industry, where high added value products can be recovered from ELTs, drastically reducing the use of composites from non-renewable sources for the production of new tyres, as well as associated CO2 emissions.

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research andinnovation programme under grant agreement No. 869625.

References

[1] S.D. Stefanidis, K.G. Kalogiannis, E.F. Iliopoulou, A.A. Lappas, P.A. Pilavachi: In-situ upgrading of biomass pyrolysis vapors: catalyst screening on a fixed bed reactor. Bioresource Technol. 102, 8261–8267 (2011)