CPERI/CERTH has long expertise in the development of catalytic processes for the production of renewable energy and other products. Our involvement in BLACKCYCLE is two-fold: optimization of the pyrolysis process of End-of-Life-Tires by applying novel catalytic pyrolysis concepts and upgrading of the pyrolytic oil via catalytic processes, such as hydrodesulphurization and aromatization. During the first year of the project, good collaboration was established between the partners and significant progress was made for each task.

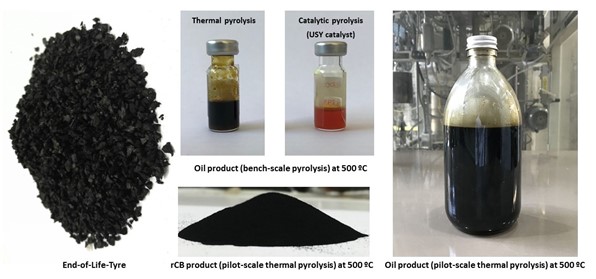

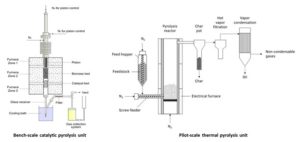

With regards to pyrolysis, we investigated the fast pyrolysis of ELTs combined with ex-situ catalytic upgrading of the pyrolysis vapors. The effect of the pyrolysis temperature (500 °C – 550 °C – 600 °C) was investigated both in bench- (g-scale) and pilot-scale (kg-scale) units (Figure 1). Good agreement between the two units was observed regarding the overall trends of the pyrolysis temperature’s impact on the product yield distribution and properties. Up next, the effect of commercial ultra-stable Y (USY) zeolite-type catalyst on pyrolysis was investigated at the optimum pyrolysis temperature (500 °C) and at variable catalyst-to-feed ratios. The USY catalyst markedly improved key oil product properties, such as the C/H molar ratio and the aromatics content. Figure 2 presents the pyrolysis products from the bench- and pilot-scale pyrolysis of ELTs at 500 °C. Future work will focus on increasing the catalyst amount in the reactor to further improve the properties of the oil product, to the point that it meets the specifications set by BlackCycle’s partners, as well as on the pre-screening of different catalysts, with a focus on catalysts that are known to promote dehydrogenation and aromatization reactions.

The work on the upgrading of the pyrolytic oil started in the second half of the first year of the project. CERTH has already received from CSIC different fractions of pyrolytic oil (crude, heavy and light fractions) and have performed detailed characterization of these feedstocks (i.e. viscosity, density, sulphur, elemental and chemical composition, etc.) to determine the specific requirements of their upgrading via hydrodesulphurization and aromatization. We are currently synthesizing novel catalysts and will begin tests, first on small-scale, to optimize the catalysts and operating conditions, and will then perform these tests on larger, pilot-scale units.

Figure 1. CERTH’s bench-scale catalytic and pilot-scale thermal pyrolysis unit

Figure 2. Pyrolysis products from the bench- and pilot-scale thermal pyrolysis of ELT at 500 ºC