BlackCycle consortium with CERTH propose an abstract at the European Congress on Catalysis on August 27th to September 1st, 2023 in in Prague, Czech Republic.

Systematic screening of conventional and hierarchical zeolites for the catalytic conversion of end-of-life tyre pyrolysis vapours to aromatics

S.D. Stefanidis1, S.A. Karakoulia1, E. Pachatouridou1, E. Heracleous1,2, A.A. Lappas1,*

1 Chemical Process and Energy Resources Institute, Centre for Research and Technology-Hellas, Thessaloniki 57001, Greece

2 Department of Science & Technology, International Hellenic University, Thessaloniki 57001, Greece

*angel@cperi.certh.gr

Keywords:

Tyres, recycling, catalytic pyrolysis, zeolites, aromatics

Introduction.

Over 1 billion new tyres are sold globally every year, and a roughly equal number of them enter the pool of end-of-life tires (ELTs). The tyre recycling methods used nowadays do not produce materials that can be reused by the tyre industry, while ~50% of the EU’s ELTs are not recycled and are instead exported to other countries. This study is part of the EU project BlackCycle, which aims to develop a technology for the recycling of ELTs into raw materials that can be used for the production of new tyres. Via pyrolysis, ELTs can be converted into pyrolysis oil, solid and gas products. Highly aromatic pyrolysis oils can be used as feedstock for the production of virgin carbon black, which is a major component in the manufacturing of tyres. In this work, conventional and hierarchical zeolites with variable silica-to-alumina ratios (SAR) and catalyst-to-feed (C/F) ratios were screened for the catalytic conversion of ELT pyrolysis vapours towards aromatic compounds.

Experimental/methodology.

he ELT feedstock was provided by Aliapur S.A., and was described as “granules of multi-brand truck tyres 1-3 mm”. The conventional zeolites used were Y zeolites with SAR 5 and 30, a ZSM-5 zeolite with SAR 80 and a Beta zeolite with SAR 25, all purchased from Zeolyst. Hierarchical Y and ZSM-5 zeolites were used as well. The hierarchical Y was synthesised by desilication of the commercial Y SAR 30 (Y SAR 30 DS), while the hierarchical ZSM-5 was synthesised by desilication of the commercial ZSM-5 SAR 80 (ZSM-5 SAR 80 DS). The screening was carried out in a bench-scale fixed bed reactor using 2.8 g of ELT and C/F ratios of 0.25, 0.5 and 1. Both the pyrolysis and the catalytic conversion temperatures were 500 °C.

Results and discussion.

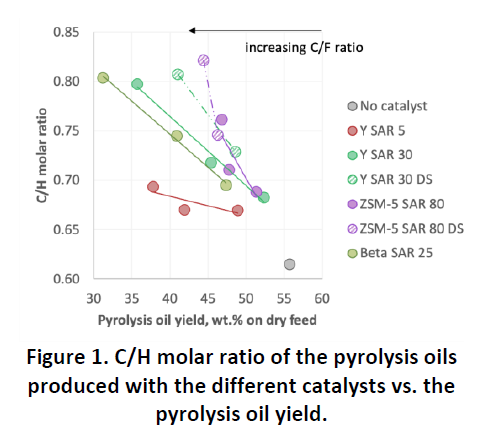

Upgrading the ELT pyrolysis vapours with any of the zeolites used resulted in a decreased yield of pyrolysis oil in favour of permanent gases and coke formed on the surface of the zeolites. However, this was accompanied by a significant increase in the aromaticity of the pyrolysis oils, as indicated by their increased C/H molar ratio (Figure 1). In the case of the Y zeolites, the Y SAR 5 resulted in the most modest increase of the C/H ratio, which indicated that its high density of acid sites was not favourable for the efficient conversion of the ELT vapours. On the other hand, the Y SAR 30 achieved significantly higher C/H ratios when compared to the Y SAR 5. The Beta SAR 25 achieved similar C/H ratios as the Y SAR 30, but with reduced pyrolysis oil yield. The ZSM-5 SAR 80 achieved a more moderate increase in the C/H ratio, accompanied by a moderate decrease in the pyrolysis oil yield. This was attributed to a lower activity of the ZSM-5 SAR 80, which in turn was attributed to the small pores of the ZSM-5 structure. Finally, the hierarchical zeolites Y SAR 30 DS and ZSM-5 SAR 80 DS exhibited higher activity and achieved the highest C/H ratios in the pyrolysis oils, while at the same time, they achieved a more moderate reduction of the pyrolysis oils yield compared to their conventional counterparts.

Acknowledgements:

This work has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 869625.