Pyrum Innovations takes a step further for the CO2 reduction.

Analysis by Fraunhofer Institute confirms enormous CO2 reductions for Pyrum’s pyrolysis process compared to conventional recycling processes for end-of-life tyres.

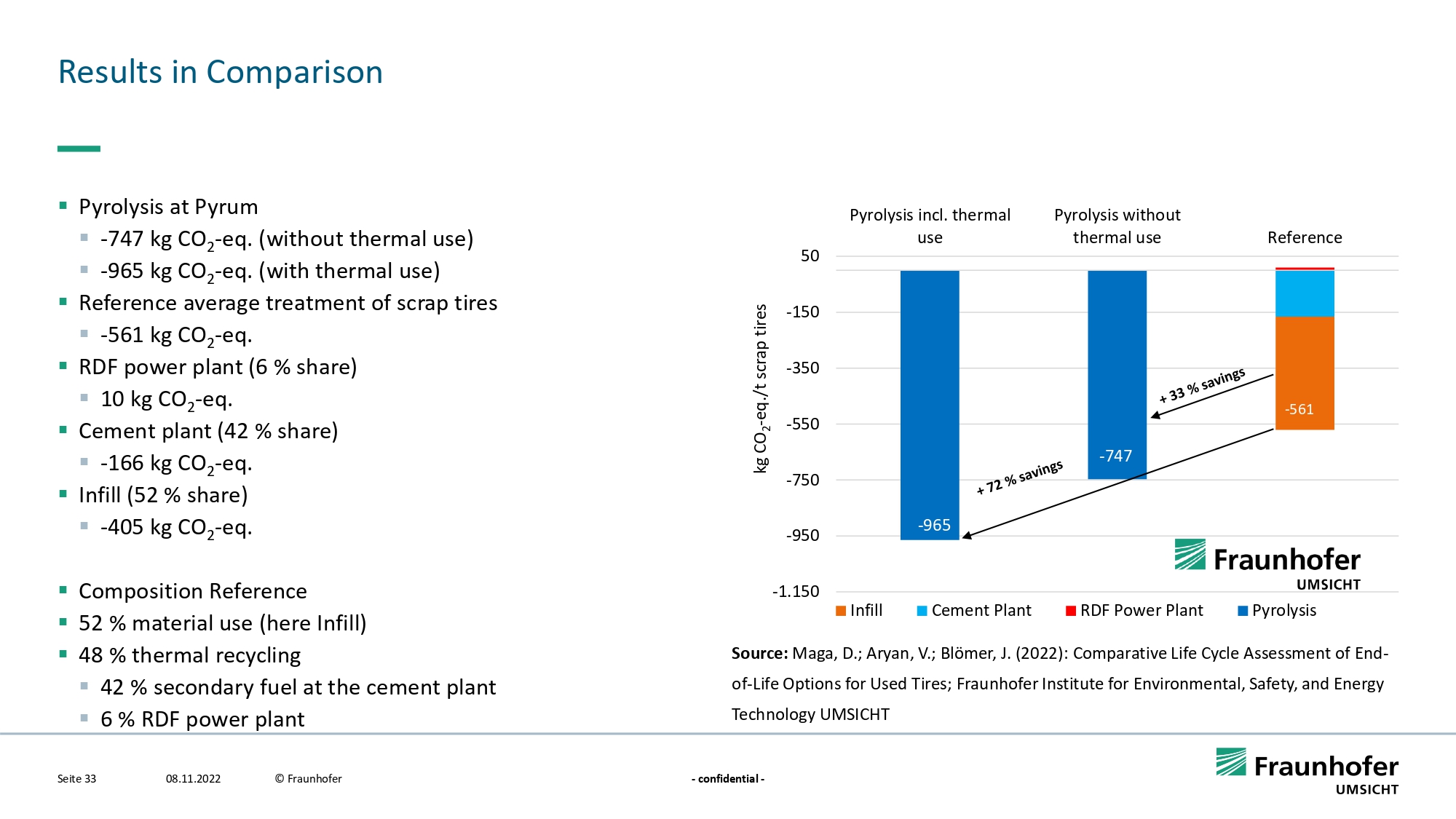

Pyrum has for the first time obtained a determination of the CO2 savings of its pyrolysis process as part of a « Life Cycle Assessment » (LCA, eco balance) by the Fraunhofer Institute for Environmental, Safety and Energy Technology. The results once again demonstrate the unique and sustainable efficiency of the Pyrum technology. Compared to the use of fossil raw materials, Pyrum’s process saves 747 kg CO2 equivalent per tonne of ELT; if the use of the waste heat produced is included, as Pyrum is already applying, even 965 kg CO2 equivalent are saved per ton of ELT.

By comparison, the current recycling mix in Germany achieves savings of 561 kg CO2 eq. per tonne of used tyres. In comparison, Pyrum performs up to 72% better.

Discover the role of Pyrum in the BlackCycle project